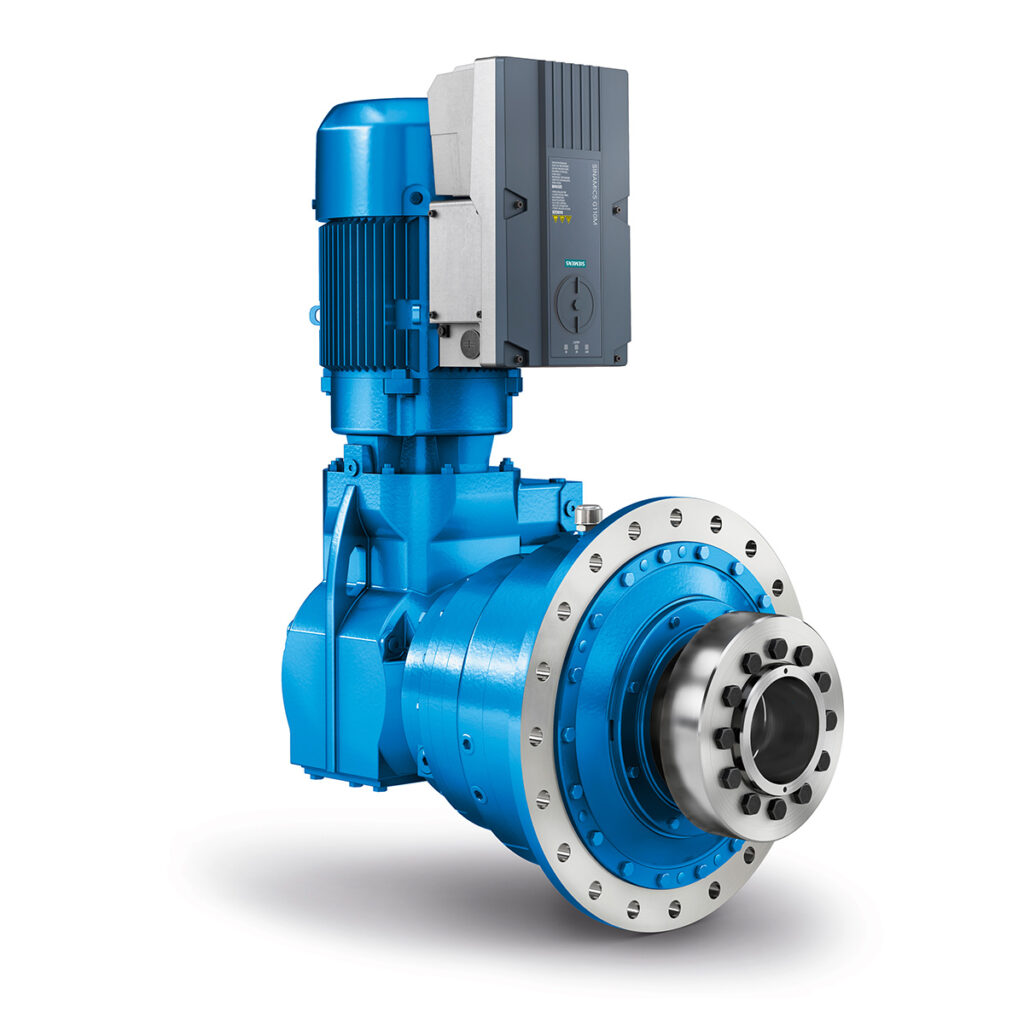

- Planetary gear unit with high power density which can be installed horizontally or vertically

- Nominal torque range from TKN = 10,000 Nm to 80,000 Nm with 8 sizes

- Nominal transition range from i = 25 to 15,000

Playmaker in the premium league

With FLENDER SIP® planetary gear units, we offer you a spectrum of fatigue-resistant, reliable and finely spaced gear unit solutions. The series includes not only the highly integrated planetary gear motor but also maximum conformity with all international motor standards and ensures that quality and performance bear a sensible relationship to life cycle costs and price.

The FLENDER SIP series covers a wide range of different gear unit models: eight frame sizes, six transmission ratios and five output shaft versions. To ensure that the gear units can be installed in any application, a number of options are available: cylindrical shafts with parallel keys or splines, hollow shafts with shrink disks or splines and flanged shafts. Coaxial and 90° FLENDER SIP gear units offer a very finely spaced spectrum of transmission ratios with up to 53 steps. The accessory program provides all the necessary connecting adapters for standard motors, including connections to IEC and NEMA motors as well as to servomotors.

Furthermore, temperature control, explosion protection, taconite seals, a design for temperatures down to –40 °C and various mounting options guarantee optimal availability and fail-safe operation even under demanding ambient conditions.

With FLENDER SIP, reliability and flexibility become a product. Benefit from the special FLENDER SIP qualities in the premium league and get the efficiency you want.

Your benefits at a glance

- Greatest power capacity and highest reliability

- High efficiencies and best performance

- Finely spaced transmission ratios with up to 53 steps

- Maximum flexibility when selecting the motor due to conformity with all international motor and interface standards

- Five output shaft versions for easy connection to the work machine

- Available as an individual gear unit or as an Integrated Drive System

Made in Germany, worldwide in use

- Mining and Cement: apron conveyors, bunker dischargers, scratchers

- Steel Production: pilger rolling mills and reversing rolling mills

- Food and Beverage: mixers

- Other fields of application: chain conveyors

Did you know?

The combination of the FLENDER SIP with the SIMOGEAR geared motors results in an incredibly wide selection of product variants. This means that almost any drive task can be solved ideally.